Marine Vessels

Delivering certainty from shallow to ultra-deepwater

Our versatile marine vessel fleet fuels our ability to support some of the world’s most complex offshore projects, ranging from shallow to ultra-deep-water depths. Through ownership of our fleet, we deliver streamlined project execution, increased efficiencies and reduced emissions relevant to project delivery.

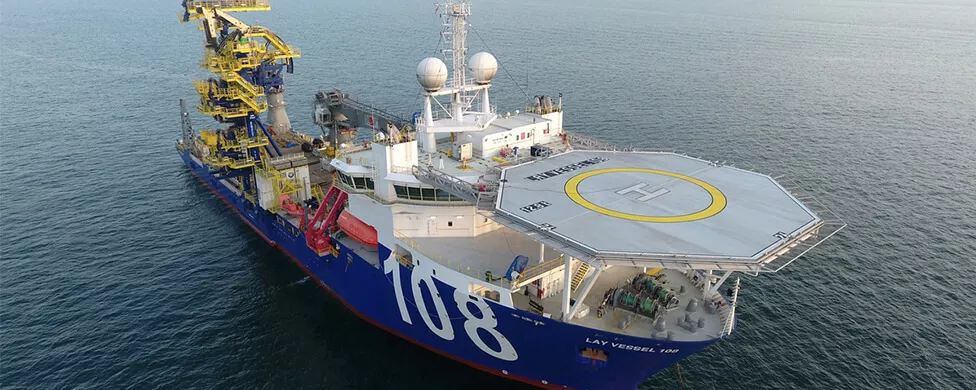

Fast-transit, dynamically positioned (DP2) construction vessel with an ultra-deepwater J-lay system rated for 1,653 ST [1,500 MT] dynamic accompanied by two 440 ST [400 MT] Offshore Mast Cranes.

- Proven in the Gulf of Mexico, and West Africa

- Delivered an advanced ultra-deepwater pipelay system with a high-level of automation

- 2800+ meters deepest pipelay

- Fully enclosed 1,653 ST [1,500 MT] dynamic hex joint J-Lay system rated for 11,483 ft [3,500 m] water depth

- Two 440 ST [400 MT] Offshore Mast Cranes for single fall operations 220 ST [200 MT] up to 16,404 ft [5,000 m] dual fall operations 440 ST [400 MT] up to 8,202 ft [2,500 m] water depth complete with Active Heave Compensation (AHC) and Tandem Operations Capability

- Pipe storage capacity of 11,023 ST [10,000 MT]

- Deck cargo capacity of 8,818 ST [8,000 MT]

- Shallow water pipelay barge with 3,080 ST [2,794 MT] Derrick crane

- S-lay capability from 4 to 60 inches with truss or articulated shallow water portable stinger.

- 12-point anchor mooring system, up to 250 MT lay tension capacity and 10 ramp stations.

- Long track record and performance of worldwide operations.

- Unique combination ultra shallow water pipelay barge with 1,650 ST [1,500 MT] derrick crane

- S-lay capability from 6 to 60 inches with truss or articulated shallow water portable stinger.

- 10-point anchor mooring system, up to 120MT lay tension capacity and 10 ramp stations.

- Eco-friendly in terms of lower fuel consumption and sustainable barge.

- Special purpose ship notation for worldwide operations

- Upgraded to deliver greater reliability and versatility for offshore construction projects.

- Derrick crane lifting capacity up to 4,000 MT.

- Improved station keeping with new DP2 control, switchgear, and power management system.

- DP2 compliant dynamic positioning system

The DLV 2000’s combination of S-lay, heavy lift, large deck space and accommodation coupled with efficient transit speed provides McDermott with a versatile asset that can effectively execute projects in all major oil and gas basins around the globe.

- Versatile combination heavy lift and pipelay vessel with 2,200 ST [2,000 MT] crane

- Multiple cranes for construction, pipeline and deepwater installation

- S-lay capability from 4.5 to 60 inches [114.3 mm to 1,524 mm] with high strain, deepwater stinger

- Pipelay operations in single- or double-joint configuration

- DP3 compliant dynamic positioning system

Ideally configured for deepwater jacket launch and large deck floatover installation projects.

- Second-largest floatover installation vessel in the world

- Four double-action hydraulic jacks can be arranged to load a structure from shore and reposition it offshore for launching or floatover installation

- Sensitive ballast system fitted using diesel pumps and 16 hydraulically operated rapid flood bottom valves

- Centrally located controls including remote tank level gauging

Fast-transit, dynamically positioned (DP 2) vessel with modern, efficient and versatile flexible and umbilical lay system.

- Modern, efficient and versatile flexible and umbilical lay system

- 165 ST [150 MT] Vertical Lay Tower

- 165 ST [150 MT] A&R system

- Reel Drive System (RDS) – 5 reels at 440 ST [400 MT] each

- Optional 2,200 ST carousel

- 3,750 ST [2,000 MT] overall product payload @ 90% fuel load

- 440 ST [400 MT] main crane capacity

Fast-transit, dynamically positioned vessel with a vertical lay system for flexible product across a wide variety of water depths.

- 2800+ meters deepest pipelay

- Modern flex-lay vessel designed for global operations

- Pipelay capability from 50 mm to 620 mm

- Basket/Bobbin carousel with 4,000 MT capacity

- Flex-lay tower with 300 MT single tensioner

- Main crane lift capacity 250 MT