Our culture of innovation drives industry firsts and improves the safety, reliability and performance of storage facilities, tanks and terminals.

Across the markets we serve, our products and services meet the varying needs of major industrial and technical developments. We are continually evolving our solutions to meet changing market demands.

Our commitment to innovation began more than a century ago and remains evident in every project we deliver.

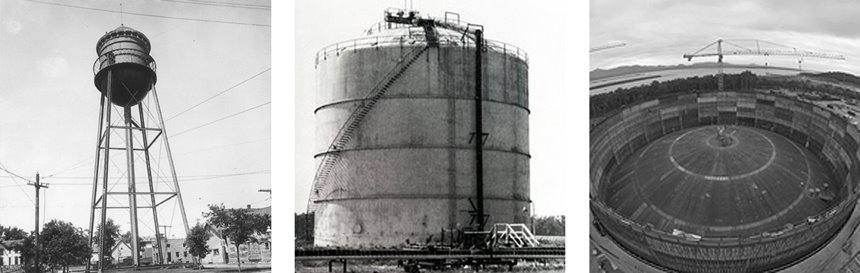

Water Storage Pioneers

In 1884, CB&I erected its first steel elevated water storage tank designed with a full hemispherical bottom, the first of many technical innovations in water storage. We pioneered the transition from riveted tanks to welded steel tanks in the 1930s and built our first Watersphere® elevated water storage tank in 1939. The single-pedestal design of the Watersphere and subsequent Waterspheroid®—which was introduced in 1954—have proven to be one of the most reliable elevated water tank designs in the United States.

Setting the Standard for Oil & Gas

In 1919, CB&I built its first oil storage tank and began to specialize in steel plate structures, establishing the beginning of a long association with the oil and gas industry. Designed to reduce product loss and fire hazards, in 1923, we introduced the world’s first floating roof tank which has since become the industry standard for the safe and economical storage of petroleum products. No project is too big or too small for CB&I. We’ve built 101 cone roof and floating roof tanks in only 338 days for one of the world’s largest oil companies and still hold the record for the largest storage tank erected in the world, with a diameter of 412 feet and a capacity to store 1.5 million barrels.

LNG Industry Innovators

From the beginning, we have innovated the LNG storage industry. In 1958, we built the world’s first double-wall insulated tank for the storage of liquid methane, now more commonly known as LNG. In 1965, we designed and constructed the world’s first commercial LNG peak shaving plant for gas. By 1971, we built the first U.S. marine LNG storage and distribution terminal. Now, we are a recognized leader in the design and construction of LNG storage systems.

Advancing Construction Techniques

We are continuously refining and advancing the technology, equipment and construction methods that support our global operations. CB&I opened its fully-equipped welding lab centered around research and development in 1954, which continues to develop and test welding processes today. In 1962, we pioneered the concept of air raising tank roofs, an installation method that significantly reduces construction time. Our construction technology group is a clearing house for construction best practices and developed the patented scaffold-less tank erection method in 1998.

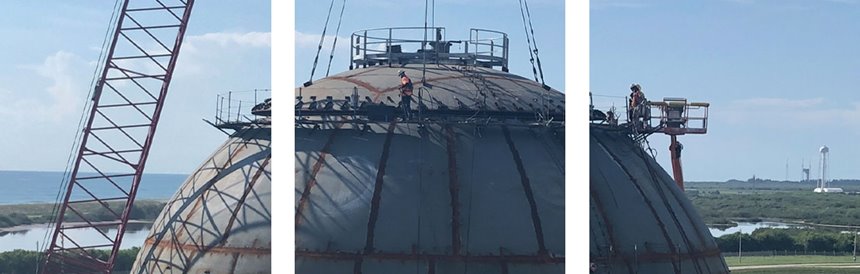

Scaling Up Technology to Meet Future Demands

CB&I built the first liquid hydrogen sphere in 1960 with the capacity to store 170 cubic meters. Over the last sixty years, we have expanded that threshold by about 30-fold to 5,000 cubic meters. In 2020, CB&I Storage Solutions began building the world's largest liquid hydrogen sphere for NASA in Cape Canaveral, Florida. This sphere will provide NASA with the capacity to store 5,000 cubic meters of liquid hydrogen to support the Moon to Mars Exploration Program. We continue to develop technology to expand existing liquid hydrogen storage capacity limits to unlock even greater potential in this field.